Multifunctional Desktop Automatic Pharmaceutical Machinery

Equipment Round Bottle Labelling Machine

Product Overview of Bottle Labelling Machine

1. Applicable to the pharmaceutical, food, cosmetic and other

industries, the circumference of the round object and high

precision are (double standard) and the fixed point and position on

the back label; Can also meet with taper product labeling

requirements.

2. The advanced affinity man-machine interface system, easy

operation, complete function, has the rich online help function.

3. Unique bottle at three-point position, avoid to linear labeling

machine labeling bottle is irregular, and the bottle is not caused

by the error of vertical labeling skew, then it let labeling more

accurate, beautiful, caresses.

4. Automatic photoelectric detection, it has the function that

nothing come from conveyor and no stick label and without label

automatic correction or alarm automatic detection function, prevent

leakage and waste.

5. The machine structure is simple, compact, easy to operation and

maintenance.

Product Parameters of Bottle Labelling Machine

| Speed | 20-40pcs/min (depends on actual size of the bottles and labels) |

| Bottle Diameter | 20-80mm |

| Accuracy | 1mm |

| Voltage | 220v 50hz |

| Power | 1.2kw |

| Weight | 69KG |

| Size | 1300*900*1550mm |

Feature of Bottle Labelling Machine

1) Control system: Use SIEMENS brand PLC control system, with high

stable operation and extremely low failure rate.

2) Operation system: The man machine control 7 inch touch screen,

directly visual interface easy operation, rich with help

function and fault display function.

3) Check system: Use German LEUZE check label sensor, automatic

check label station, stable and convenient don't have much higher

requirement for worker.

4) Send label system: German Avery labeling engine control system,

stable with high speed.

5) Alarm function: Such as label spill, label broken or other

malfunction during machine working all will alarm and stop working.

6) Machine Material: Machine and spare parts all use material S304

stainless steel and anodized senior aluminum alloy,with high

corrosion resistance and never rust.

7) Low voltage circuit all use the German Schneider brand.

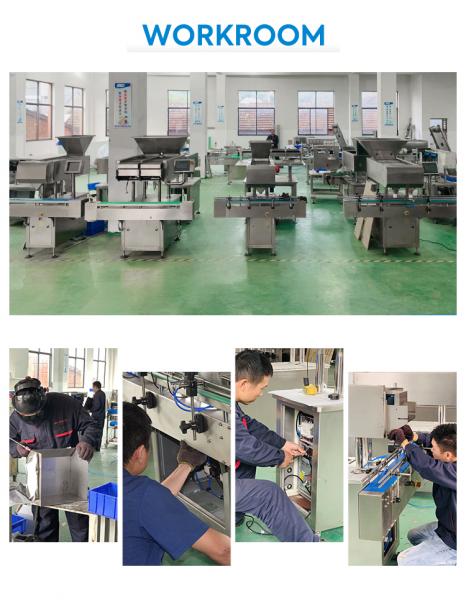

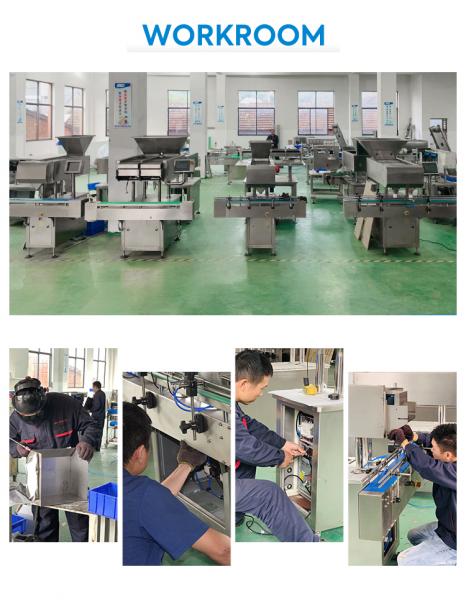

Show of Bottle Labelling Machine

Application of Bottle Labelling Machine

The machine can realize double-sided peripheral labeling and

labeling functions at the same time, which can meet the

requirements of flat bottle, square bottle and bottle-shaped

single-sided and double-sided labeling, cylindrical

full-circumference labeling, and half-circumference labeling. It is

widely used in the cosmetics industry, Daily chemical industry.